But now back to more important work...

With £800 of Marine Ply secured to the chassis I rather nervously got out the jigsaw...

I started with the step. The old maxim; measure twice, cut once, was ringing in my head. At this stage a cock-up would be costly.

A good steel edge & a heavily scored line to cut up against is the best way to get a nice clean edge in plywood.

The chassis was pretty true but it made good sense to always work off and check measurements back to the centre-line.

I first cut a generous inch wider than the template.

And the beauty of having the body-shell balanced on a chain-hoist meant it was easy to wheel the floor in and out. Checking, measuring and trimming. Little by little.

I used the off-cuts from the best preserved curve to shape the exact same shape for the others.

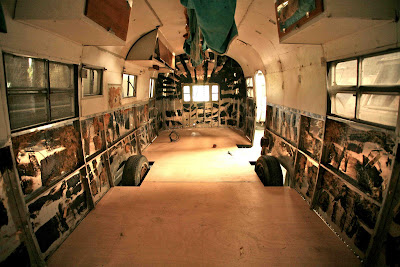

Until finally the body dropped snugly onto the new floor.

The outer sheets overlapping the plywood and the rivet holes lining up ready to be re-rivetted to the C-channel which will be the next thing to fit.

.jpg)